Manufacturing Process Optimization Project

Electronic Industry - Process Optimization

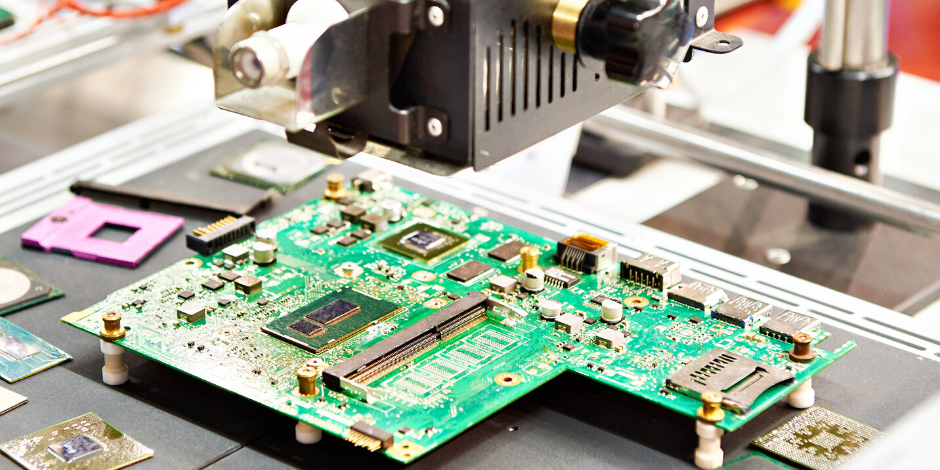

Project to improve productivity, reduce in-process inventory and reduce the use of manufacturing area. In this project, 20 managers and 50 engineers and analysts were trained with the Lean Board Game and later 5 Kaizen projects were carried out at the factory. The total duration of the project was 2 months and the kaizens were carried out in a week. The project's gains were very significant and lasting, which allowed a great gain in productivity. With the same team, the amount of products manufactured per day was increased by 18%! Gains in stock, use of manufacturing area and reduction of assembly problems were also possible.